Rapid Excellent rapid exit milking parlour

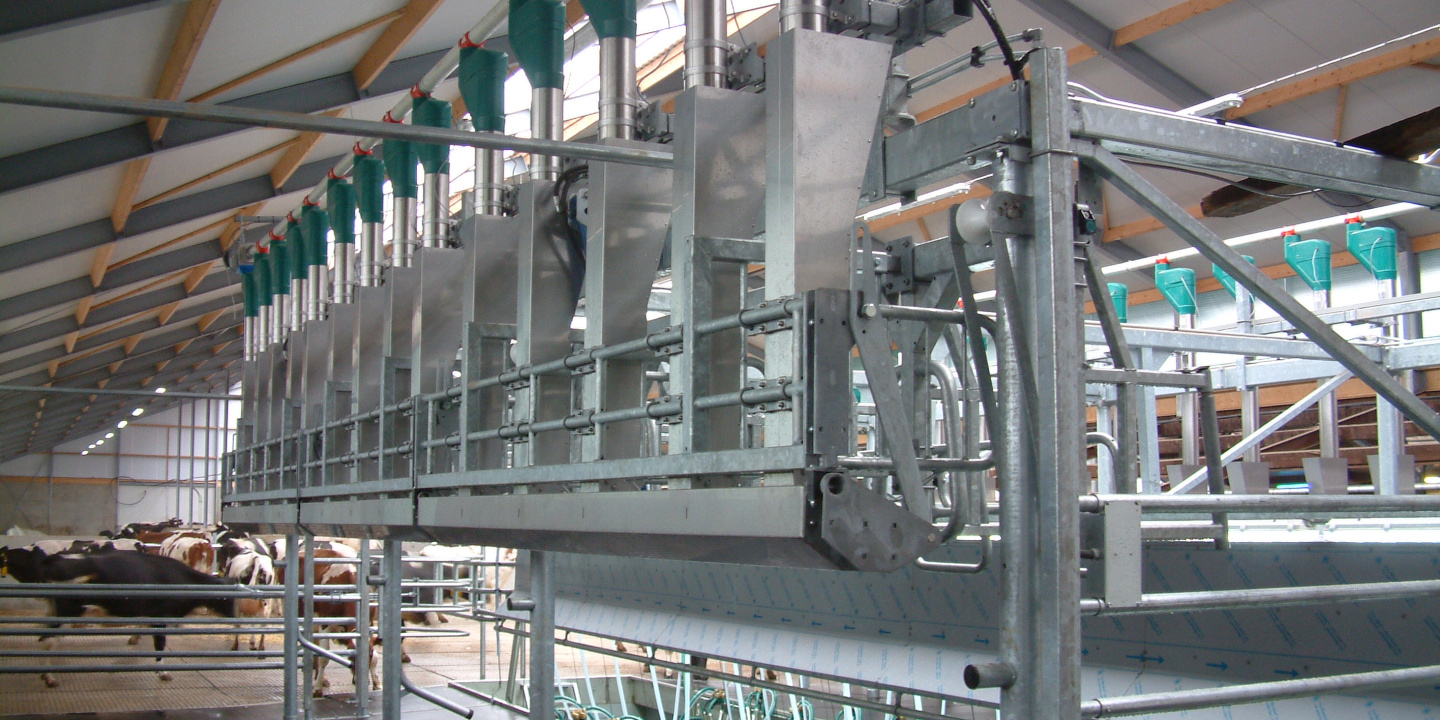

The Rapid Excellent is an advanced side-by-side Rapid Exit milking parlour, a proven concept for good and reliable milking. Characteristic is its solid, robust construction. The breast barriers move vertically upwards by means of an electro-hydraulic system and do not swing forward and therefore allows the cows to exit the milking parlour simultaneously via the broad exit lane.

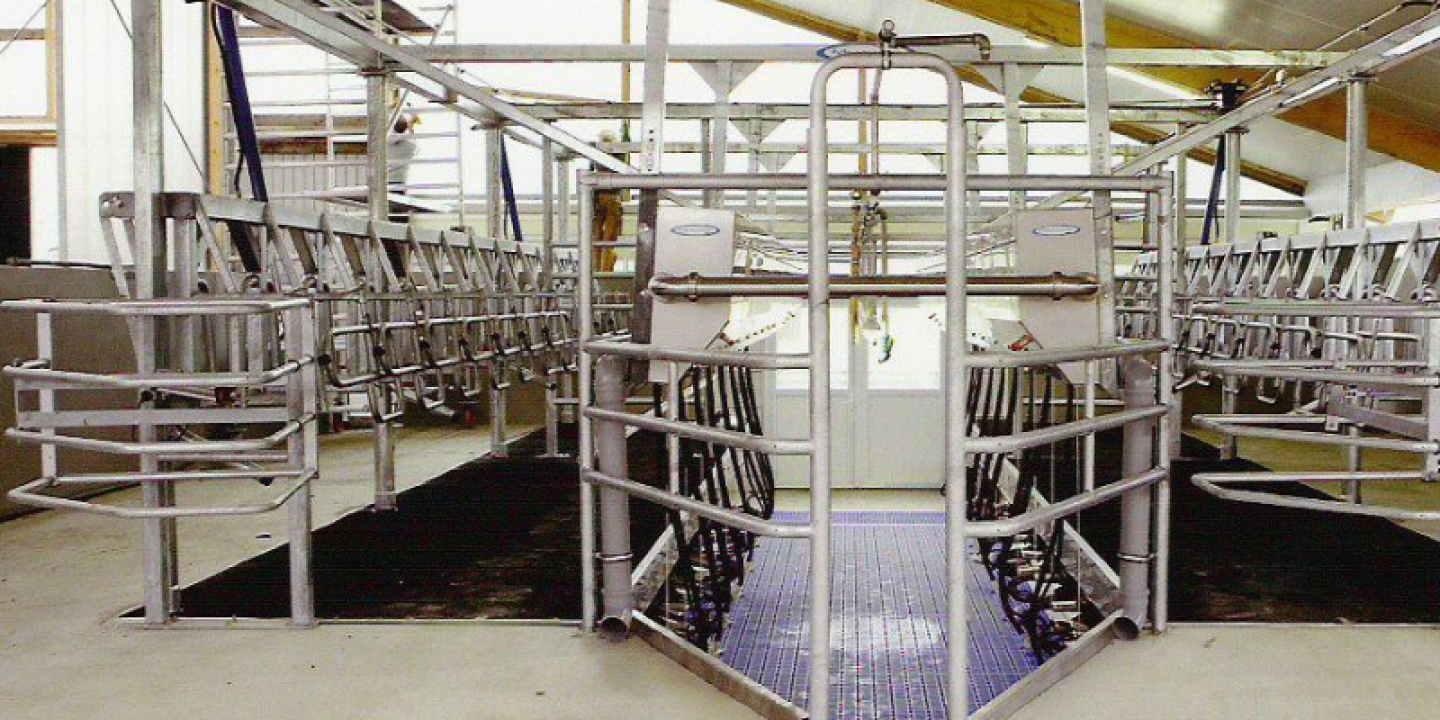

The Rapid Excellent is equipped with practical gates. As soon as the first cow has placed itself in the first position, there will be an opening for the second cow to enter the second one. This procedure is repeated until all positions are filled. Thanks to the optimal gate model it is perfectly possible to milk the cows in a partially filled milking parlour. Because the cows stand close to each other, short walking lines are created, which constitute a significant time-saving factor.

The hydraulic, reliable operation with electrical control makes stepless indexing possible. The Rapid Excellent milking parlor can be supplied with a stainless steel manure plate or optionally with a manure chute. This milking parlor can also be supplied with a beautifully finished stainless steel pipe cabinet, so that your pipes and cables disappear from view, which also benefits hygiene and the lifespan of your equipment.

The breast barrier moving vertically upwards and the absence of floor-mounted supports on the floor between the cows, allow large cows sufficient space to walk away. Therefore, this milking parlour requires only minimal space.

To ensure optimal hygiene and safety for the operator, the frame is self-supporting and equipped with kick protection. By default, the milking parlour is equipped with a stainless steel manure plate and gutter edge, optionally available with manure gutter, transparent plate, or open central frame.

Unique elements are electrohydraulic and indexable breast barriers, so that the position length can be easily shortened by adjusting the breast barrier, allowing the udders of the cow to be optimally accessible for optimal working comfort. Furthermore, the breast barrier is shaped in such a way that the cow is extremely relaxed during milking.

As a option are driving clamps on our Rapid Excellent milking parlour bracket available. After raising the breast barrier, the animal-friendly driving clamp can be activated, so that the cows can leave the stall quickly. This accelerates the rotation of the cows and will thus speed up the entire milking process considerably.This clamp can also be fitted to existing Rapid Excellent milking parlours.

Optional

- Automatic expulsion system, a livestock-friendly solution for very quick driving

- Foldable breast rail for individual selection

- Individual indexing

- Manure gutter including grid, transparent plate, or open central frame

- Position width of 720 or 750 mm

- Lockable stainless steel feeding troughs for concentrated feed individually or in groups

- Stainless steel cabinet for protecting pipelines and equipment

- Entry gates supplied to suit your requirements, with fencing for entry funnel

- In case of hydraulic control, an energy-efficient automatic start-stop function is available

- Higher walk-through height

Advantages

- Robust construction for long operational life

- The central frame has no supports and is equipped with kick protection for safe milking

- Breast barriers move upwards vertically, do not swing forward, and therefore require minimal installation space

- Stepless indexing operated by a push button, allowing the udders of the cow to be optimally accessible

- High-capacity silent unit for quick changeover, with steel pipes

- Low-maintenance selection gates with rubber coating and grease nipples

- Front gate moving only vertically upwards, allows broad exit lane

Technical information

- Uprights made of thick-walled tubing with reinforced base

- Frame and breast barrier made of heavy-duty, locally reinforced profile tubing

- Front gate moving vertically upwards with a free walk-through space of 1650mm

- Shock-proof nylon diabolo-guided rollers with stainless steel axles

- Standard position width 700 mm centre to centre

- By default, stainless steel manure plate and kick protection

- Shock-proof nylon diabolo-guided rollers with stainless steel axles

- From 20 positions upwards equipped with a unique and reliable pull bar lift system

- The walk-through distance between selection gates and central frame is adjustable

- Hot dip galvanised construction, inside and out

- Supplied with assembly and instruction manual and CE conformity declaration